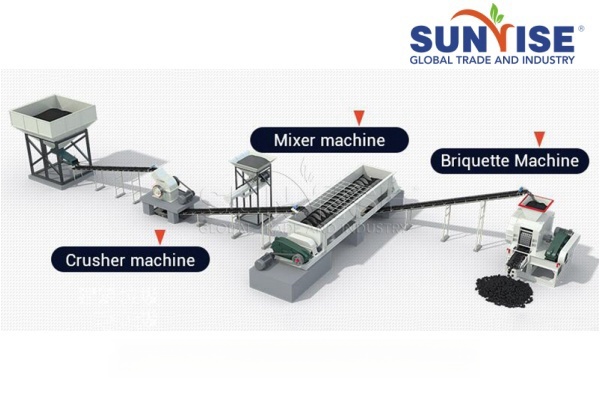

Rice husk charcoal briquettes offer an innovative and sustainable solution for utilizing agricultural waste. As the by-product of rice production, rice husks are often discarded or openly burned, contributing to environmental pollution. However, by converting these husks into charcoal briquettes, they become a valuable resource for clean energy. The transformation process involves several machines, each playing a critical role in producing high-quality charcoal briquettes.

Rice Husk Grinder

The journey from rice husks to charcoal briquettes begins with grinding. The rice husk grinder is a machine designed to crush the husks into fine particles. This step is essential as it increases the surface area of the husk, making them more amenable to subsequent processes and ensuring uniformity in the final product. A well-ground husk facilitates efficient carbonization and briquetting, leading to higher-quality briquettes.

Carbonization Furnace

Once the rice husks are ground, they undergo carbonization. The carbonization furnace is a specialized kiln that converts the organic material into charcoal by heating it in a controlled, oxygen-limited environment. This process removes volatile compounds, leaving behind a carbon-rich substance. Modern carbonization furnaces are designed to be efficient and environmentally friendly, often equipped with features to capture and utilize the gases released during the process.

Charcoal Pulverizer

After carbonization, the charcoal may require further processing through a charcoal pulverizer. This machine grinds the larger charcoal pieces into finer particles, ensuring consistency in size and texture. This step is crucial for achieving the right composition and density in the final briquettes, which impacts their burning efficiency and overall performance as a fuel source.

Briquette Press

The heart of the rice husk charcoal briquette production is the briquette press. This machine compresses the powdered charcoal into solid briquettes under high pressure. Briquette presses come in various designs, including hydraulic, mechanical, and screw presses, each suited to different scales of production. During this stage, a binding agent may be added to ensure the briquettes hold their shape. The result is a uniform, compact briquette that is easy to handle, store, and transport.

Drying System

After pressing, the briquettes may still contain residual moisture, which needs to be removed to enhance their combustion properties. A drying system, often comprising conveyor dryers or rotary dryers, is used to reduce the moisture content to an optimal level. Proper drying ensures the briquettes are ready for immediate use or packaging.

Packaging Machine

The final step in the production process involves packaging the briquettes. A packaging machine ensures that the briquettes are packed efficiently and securely, often in moisture-proof bags or boxes. This step is crucial for maintaining the quality of the briquettes during storage and transportation.

Conclusion

The production of rice husk charcoal briquettes is a multi-step process that relies on specialized machinery to transform agricultural waste into a valuable energy resource. Each machine, from the grinder to the packaging machine, plays a vital role in ensuring the efficiency and quality of the final product. By leveraging these technologies, the process contributes to sustainable waste management and clean energy production, highlighting its significance in today’s environmentally conscious world. Visiting: https://www.char-molder.com/2024/07/08/how-to-produce-rice-husk-charcoal-briquette-in-japan/

Leave a Reply