Palm kernel shells (PKS) are an abundant byproduct of palm oil mills, and they can be transformed into high-value charcoal for industrial fuel and specialty carbon markets. A strong business plan links three essentials: steady raw material supply, consistent product quality, and reliable buyers willing to pay export-grade prices. With the right setup, palm shell charcoal can become a scalable venture that upgrades an agricultural residue into a tradable commodity.

Securing Raw Materials and Supply Agreements

The foundation is feedstock access. Palm shells are typically sourced directly from palm oil mills through long-term contracts that specify volume, moisture limits, contamination thresholds (stones, metal, fiber), and delivery terms. Pricing can be fixed, indexed, or negotiated seasonally. Because shells vary by mill and storage conditions, your plan should include incoming inspection, covered storage, and a simple grading system to reduce variability. A dependable supply chain lowers production interruptions and improves profitability more than almost any other single factor.

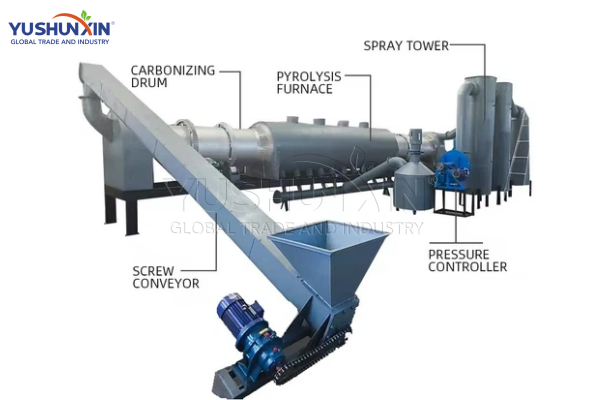

Production Process: Carbonization and Quality Control

Palm shells are carbonized in low-oxygen conditions using kilns or continuous carbonization units. The goal is to drive off volatile compounds and leave a stable, high-carbon product. Key operating targets include controlled temperature, adequate residence time, and uniform heating to avoid under-carbonized material (too smoky, low fixed carbon) or over-burned fines (loss of yield). Screening and crushing help achieve standard particle sizes, while magnetic separation removes tramp metal. Quality control should track moisture, ash content, fixed carbon, volatile matter, calorific value, and size distribution—metrics that buyers often require in a certificate of analysis.

Upgrading to Export-Grade Specifications

Export customers typically expect clean, dry, consistent charcoal. That means proper cooling (to prevent spontaneous ignition), final drying when needed, and dust management to reduce fines. Packaging is part of “grade”: jumbo bags for industrial users, or smaller bags for distributors, each with clear labeling and batch traceability. If your target market is activated carbon producers, you may need tighter specs on ash and hardness, plus more rigorous sampling and documentation.

Market Strategy, Sales Channels, and Pricing

Palm shell charcoal can be sold domestically to boilers, cement plants, and metal processing facilities, or exported to buyers seeking renewable solid fuel alternatives. The business plan should identify target countries, import requirements, and preferred Incoterms (FOB, CIF). Pricing is influenced by fixed carbon, ash, moisture, and size—so your operational controls directly affect revenue. Where possible, secure off-take agreements to stabilize cash flow and justify equipment investment.

Operations, Compliance, and Risk Management

Plan for permits, emissions control, worker safety, and fire prevention—charcoal production is heat- and dust-intensive. Include contingencies for feedstock shortages, shipping delays, and quality claims. With disciplined procurement, tight process control, and buyer-aligned specifications, a palm shell charcoal operation can move confidently from raw shells to export-grade product and build a durable, margin-driven business. Visiting: https://www.ysxcharpro.com/product/palm-charcoal-production-line/

Leave a Reply