A charcoal briquette production line transforms low-cost biomass and charcoal fines into uniform, high-demand fuel products for household cooking, restaurants, and industrial users. A strong plan for the line starts with raw material selection, then moves through carbonization (if needed), crushing and mixing, briquetting, drying, and packaging. Profitability comes from consistent quality, efficient energy use, and dependable distribution channels that can absorb steady volumes.

Raw Materials and Feedstock Strategy

Most briquette plants use materials such as coconut shells, sawdust, rice husks, peanut shells, bamboo, or charcoal dust from existing charcoal producers. Your first decision is whether you will buy ready-made charcoal fines or produce charcoal in-house from biomass. Buying fines reduces complexity, while in-house carbonization gives you more control over ash content, fixed carbon, and supply security. A good production plan includes moisture targets (often below 10–12% for smooth pressing), storage space for seasonal supply, and simple incoming inspection to prevent stones, soil, or wet feedstock from damaging equipment.

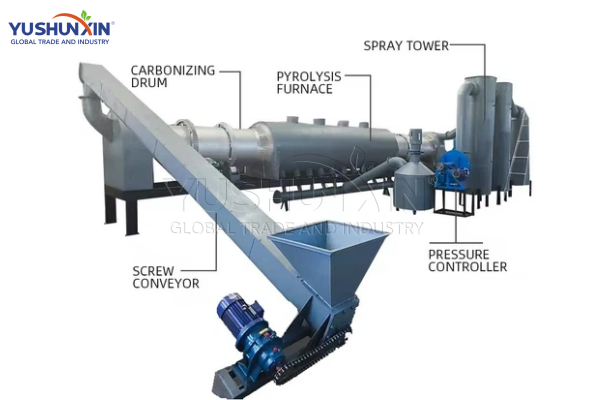

Carbonization and Char Preparation

If the line includes carbonization, outline the kiln type (traditional, metal kilns, or continuous carbonizers) and explain how you will manage smoke and heat recovery. After carbonization, the charcoal must be cooled safely, crushed, and screened. Consistent particle size helps briquettes bind evenly and reduces breakage during transport. A hammer mill or crusher and a vibrating screen are common choices, with dust control measures to improve safety and cleanliness.

Mixing, Binding, and Briquetting

The mixing stage determines final product strength. Common binders include cassava starch, corn starch, or molasses blends, chosen based on cost and market preference. The mixer should produce a uniform blend of charcoal powder, binder, and water—too dry causes cracking; too wet slows drying and leads to deformation. Briquetting machines vary by product: pillow-shaped press briquettes for mass markets, or extruders for hexagonal/shisha-style briquettes. Your plan should specify capacity per hour, mold options, and spare parts for wear components.

Drying, Packaging, and Quality Control

Drying is often the bottleneck. Options include solar drying racks, cabinet dryers, or belt/conveyor dryers using biomass heat. Targets typically include low final moisture and high compressive strength for clean burning and minimal smoke. Packaging should match buyer needs: small retail bags for households or bulk sacks/cartons for wholesalers. Simple quality tests—drop resistance, burn time, ash percentage, and ignition ease—help maintain customer trust and reduce returns.

Sales Channels and Profit Drivers

The most profitable briquette businesses lock in repeat buyers such as BBQ restaurants, shisha lounges, and distributors. Margin improves when you reduce binder costs, optimize drying energy, and sell graded products (premium low-ash briquettes vs. standard). With reliable feedstock, disciplined quality control, and a right-sized production line, charcoal briquettes can become a scalable, resilient business that turns local biomass into steady cash flow. Visiting: https://www.char-molder.com/product/charcoal-briquette-production-line/

Leave a Reply