Bamboo biochar briquettes are emerging as an efficient, eco-friendly fuel alternative, with the potential to replace conventional charcoal and reduce deforestation. The process of producing 5 tons per day (TPD) of bamboo biochar briquettes involves several stages, each playing a crucial role in transforming raw bamboo into a sustainable energy source. This article delves into the detailed process of making bamboo biochar briquettes, highlighting the key steps involved.

Raw Material Preparation

Harvesting and Collection

The process begins with the harvesting of bamboo, a fast-growing and renewable resource. Selecting the right species of bamboo, typically those with high lignin and cellulose content, is essential for optimal biochar yield. Once harvested, bamboo is cut into manageable lengths for easy transport to the processing facility.

Drying and Pre-treatment

Before pyrolysis, bamboo must be dried to reduce moisture content, which can adversely affect the efficiency of carbonization. Typically, natural air drying or solar drying methods are employed, depending on weather conditions and available infrastructure. Pre-treatment may also involve chipping the bamboo into smaller pieces to ensure uniformity during the carbonization process.

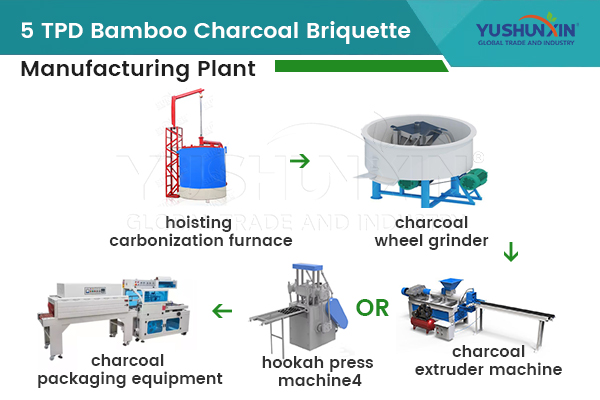

Carbonization Process

Pyrolysis

Once dried, bamboo undergoes pyrolysis, a thermal decomposition process conducted in the absence of oxygen. This is the core step in converting bamboo into biochar. The bamboo is heated in a kiln or reactor at temperatures ranging from 300°C to 600°C. The lack of oxygen prevents combustion, allowing the bamboo to carbonize, forming biochar along with by-products like syngas and bio-oil.

Reactor Design and Efficiency

The design of the pyrolysis reactor is crucial for maximizing output and efficiency. A continuous or batch reactor may be used, each with its operational advantages. Continuous reactors are more suitable for larger-scale production, like 5 TPD, as they allow for a steady flow of materials and consistent output.

Briquetting and Cooling

Crushing and Mixing

After carbonization, the biochar is crushed into fine particles. Depending on the desired properties of the briquettes, binders such as starch or clay may be added to the crushed biochar. This mixture is then homogenized to ensure consistent quality and performance in the final briquettes.

Briquette Formation

The homogenized mixture is fed into a briquetting machine, where it is compressed under high pressure to form briquettes. The shape and size of the briquettes can be adjusted based on market demand and application requirements. This step is critical for achieving the desired density and durability of the briquettes.

Cooling and Packaging

Following formation, the briquettes are cooled to ambient temperature. This step is necessary to solidify the briquettes and enhance their structural integrity. Once cooled, the briquettes are packaged for distribution. Proper packaging is vital to protect the product from moisture and mechanical damage during transportation and storage.

Quality Control and Distribution

Quality Assurance

Throughout the production process, quality control measures are implemented to ensure the briquettes meet industry standards. Parameters such as calorific value, moisture content, and ash content are regularly tested. Consistency in these parameters is crucial for maintaining the competitiveness of the product in the market.

Market Distribution

The final stage involves distributing the briquettes to various markets, locally and potentially internationally. Establishing a robust supply chain is essential to reach end-users effectively. Marketing efforts focus on the environmental and economic benefits of bamboo biochar briquettes, appealing to eco-conscious consumers and industries.

Conclusion: Sustainable Energy for the Future

The production of 5 TPD bamboo biochar briquettes involves a meticulous process that transforms a renewable resource into a valuable energy product. Each step, from raw material preparation to final distribution, plays a significant role in ensuring the sustainability and efficiency of the process. As the demand for cleaner energy sources grows, bamboo biochar briquettes represent a promising solution for reducing carbon footprints and promoting sustainable energy use. Visiting: https://www.char-molder.com/2025/01/15/how-to-make-5tpd-bamboo-charcoal-briquettes-in-india/

Leave a Reply